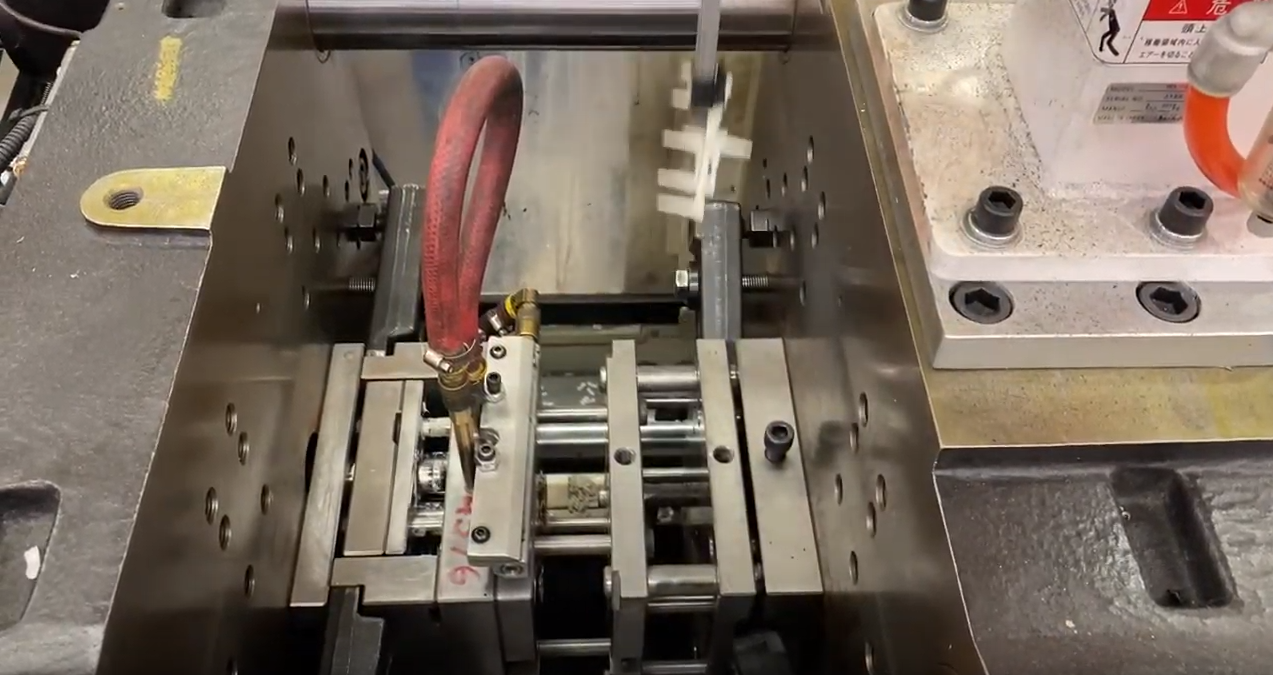

Scientific Approach

ICON is an engineering-based company that takes a scientific approach to our design, qualification and manufacturing processes. We build customer confidence by showing you results.

Quality Expertise

ICON is ISO 9001:2015 certified. Our experienced team is committed to creating custom solutions that meet our customers’ needs to truly deliver Excellence from Art to Part.

Global Experience

In this global economy, we realize that you have more choices than ever. We have complete in-house capabilities as well as domestic and offshore strategic partnerships.

New division—Serving the medical industry